What is Aluminum Foam

Aluminum foam is a lightweight material that consists of solid aluminum metal with a large number of gas-filled pores. These pores or voids are typically created by injecting gas or by incorporating a foaming agent into the molten metal during the manufacturing process. The result is a material that has a cellular structure similar to foam but is composed of solid metal.

Features

Lightweight: Aluminum foam is significantly lighter than solid aluminum, which makes it attractive for applications where weight reduction is important.

High energy absorption: The porous structure of aluminum foam allows it to absorb and dissipate energy effectively. This property makes it useful in impact and crash protection applications.

Thermal and acoustic insulation: The insulating properties of aluminum foam make it suitable for applications where thermal or acoustic insulation is required.

Buoyancy: The closed-cell structure of some aluminum foams can make them buoyant, and they may find applications in marine and underwater environments.

High surface area: The large surface area of the foam structure can be advantageous for applications such as catalyst supports or heat exchangers.

Aluminum foam has been explored for a range of applications, including in the automotive industry for crash management systems, in aerospace for lightweight structures, and in various engineering applications where a combination of lightweight and high energy absorption is desirable. The manufacturing process can vary, but it often involves a combination of powder metallurgy techniques and foaming agents to achieve the desired structure.

High energy absorption: The porous structure of aluminum foam allows it to absorb and dissipate energy effectively. This property makes it useful in impact and crash protection applications.

Thermal and acoustic insulation: The insulating properties of aluminum foam make it suitable for applications where thermal or acoustic insulation is required.

Buoyancy: The closed-cell structure of some aluminum foams can make them buoyant, and they may find applications in marine and underwater environments.

High surface area: The large surface area of the foam structure can be advantageous for applications such as catalyst supports or heat exchangers.

Aluminum foam has been explored for a range of applications, including in the automotive industry for crash management systems, in aerospace for lightweight structures, and in various engineering applications where a combination of lightweight and high energy absorption is desirable. The manufacturing process can vary, but it often involves a combination of powder metallurgy techniques and foaming agents to achieve the desired structure.

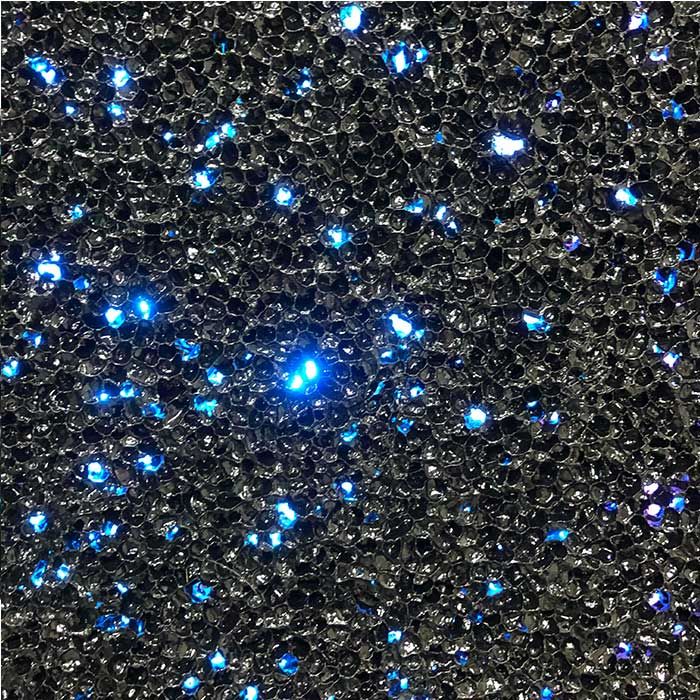

Close Cell Aluminum Foam

Foamed aluminum, the new engineering structure material, is made by adding additives to pure aluminum or aluminum alloy and undergoes a foaming process. It has both metal and bubble characteristics.According to different structure of aluminum foam, it is divided into open-cell aluminum foam and closed-cell aluminum foam.

🔹 Key Features

🔹 Key Features

- Excellent energy absorption: Ideal for impact protection

- High stiffness and strength-to-weight ratio

- Buoyant (can float in water)

- Good thermal insulation: Traps air within cells

- Corrosion resistant (less surface exposure)

- Low permeability

- Crash protection (automotive, aerospace)

- Lightweight structural panels

- Blast mitigation

- Thermal and acoustic insulation

- Architectural and design elements

| Pore diameter | 3– 8 mm | |

| Density | 0.2g/cm 3 - 0.g/cm 3 | |

| Color | We can paint different color as customer need | |

| Size availability | 520*520mm, 1200*600mm, 1000*2000mm | |

| Shape | panel, customize special shape |

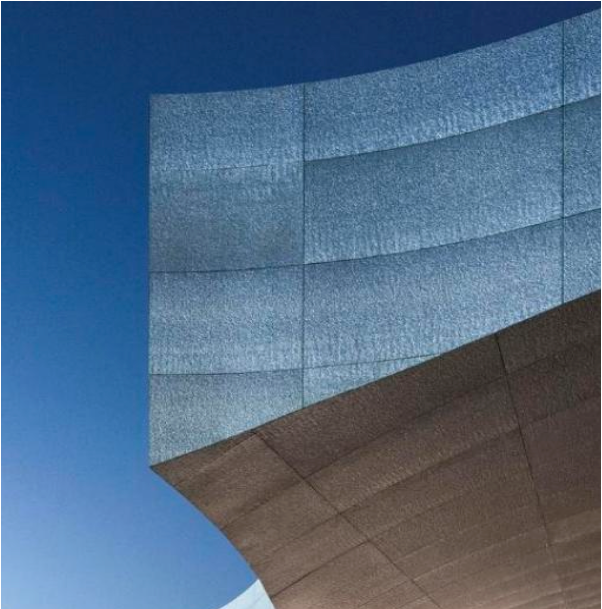

exterior cladding

exterior cladding

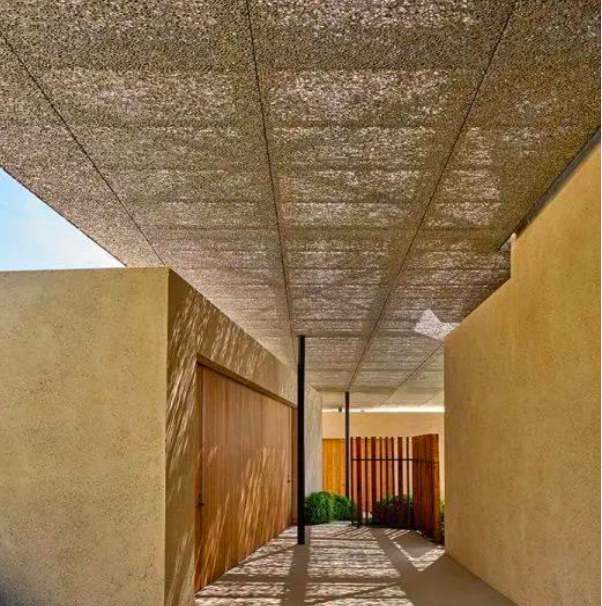

interior cladding

ceiling

Open Cell Aluminum Foam

Foamed aluminum, the new engineering structure material, is made by adding additives to pure aluminum or aluminum alloy and undergoes a foaming process. It has both metal and bubble characteristics.According to different structure of aluminum foam, it is divided into open-cell aluminum foam and closed-cell aluminum foam.The open cell aluminum foam provide beauty, strength and lightweight acoustic solutions for a variety of creative opportunities.It can be widely used for facades.

🔹 Key Features

🔹 Key Features

- High permeability: Allows gases or liquids to flow through

- Excellent thermal conductivity: Good for heat exchangers

- High surface area: Useful for catalytic or filtration applications

- Lower density than solid aluminum

- Good sound absorption: Due to the open structure

- Less structural strength compared to closed-cell

- Heat exchangers

- Filters (gas or liquid)

- Sound dampening

- Lightweight cores in sandwich panels

- Battery electrodes

Exterior Ceiling

Exterior Cladding

Interior Decoration

Interior Cladding

Address

7F. No.50, Sec.5, Nanking E.Rd. Taipei, Taiwan

© 2025 All rights reserved.

.

.